Quality: stop the solo sprint, start the collective relay

(and find out how a simple click could have prevented an accident...)

QSE manager, quality coordinator... It doesn't matter what your title or gender is: this article is aimed at those of you who deal with Quality on a daily basis.

When quality is down to one person...

In many companies, quality, safety and the environment are still perceived as a "priority". the job of the QSE manager" . The company wants Eduqua certification, and the QSE manager has to take care of everything, from the creation of processes and procedures, when there are few or none, to the introduction of risks and regulatory monitoring. They must ensure that everything is in compliance before the "last minute" audit, and woe betide them if they forget a control point that will delay certification!

We told you a few months agoWe're back with more, and this time we're immersing you in a 3D experience!

We can't stress this enough, the success of a management system depends on the commitment of everyone involved. And this collective vision changes everything.

Why collective commitment is vital

A QSE system can only survive if its employees identify with it and feel committed to it. This presupposes that they understand what is expected of them, why it is important, and above all... what they gain from it on a daily basis. Why wait until the next day if, the next day, the company has burnt down because someone didn't take two minutes to report a wiring fault?

"Prevention is better than cure, isn't it?

- Fewer breakdowns = less stress

- Fewer incidents = greater safety

- Clear processes = greater efficiency

And it's not just a question of "goodwill".

We need simple tools, clear communication and genuine recognition of their role.

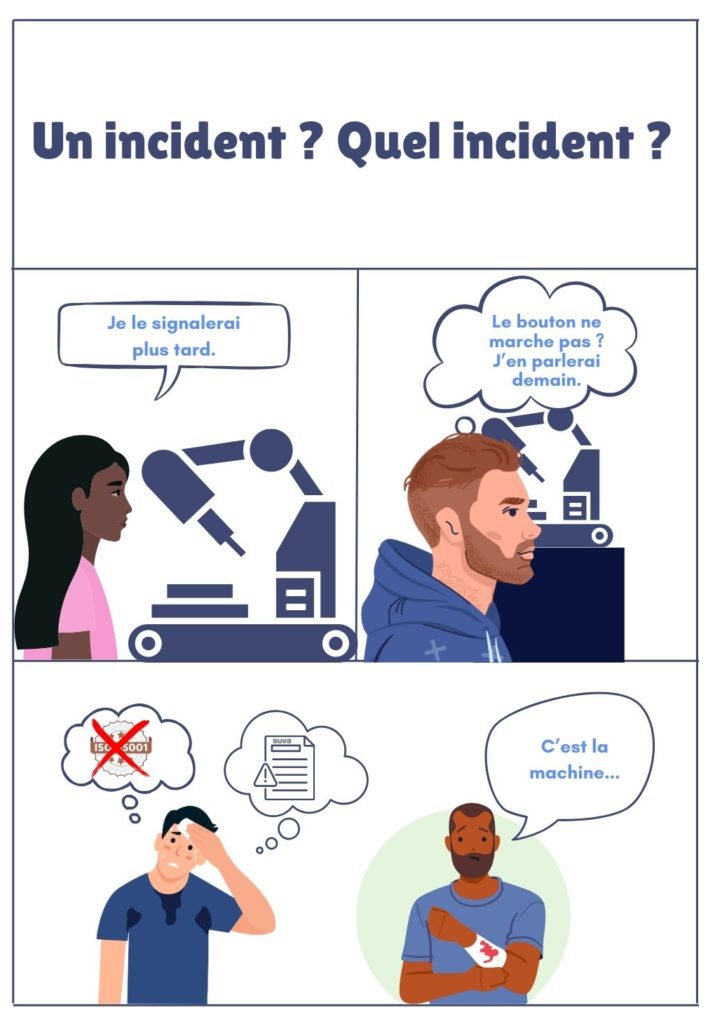

When an undeclared incident becomes an accident

💥 Let's take two minutes to tell our story

what really happened...?

Sophie works as a CNC machine operator in a small precision engineering company based in Neuchâtel. She's diligent, fast and... often multitasks. One Thursday morning, she noticed that the safety switch on her machine wasn't working properly: she had to press it several times for the machine to stop. She thought about reporting it, but between two emergencies, she forgot.

The following Friday, Léo, an enthusiastic trainee, came to observe the machine. He inadvertently touched a button, the machine activated and almost grabbed his sleeve. But no harm done.

Sophie thinks about the switch again, promises herself she'll talk about it on Monday, but the weekend passes.

🚨 Three weeks later, André, the colleague opposite, slightly injured his hand on the same machine. This time, he had to fill in a SUVA report. And above all, to explain why no-one had reported a problem that had been known about for weeks.

❌ What didn't work

- No quick and easy way to report a technical problem.

- The trainee has not been informed of the safety rules specific to this machine.

- The switch should have been repaired immediately, but the information was never circulated.

✅ What a platform like SIRIS+ would have enabled :

- A clearly visible button on the dashboard: "Report an incident".

- An automatic alert sent to maintenance and the QSE manager

- Visible monitoring in a shared incident sheet, with date, photos, actions in progress, etc.

- Safety documents directly linked to the machine, accessible via a single link

- Full traceability in the event of an internal audit or investigation

🙌 From solo QSE to collective QSE

Going from a single QSE manager in charge of everything... to a group of employees in which everyone takes action at their own level, that changes a company.

It's not about good intentions. It's about listening, working as a team, being clear... and being prepared.suitable tools. Like our platform.

And in practical terms, how do you get everyone on board?

Here are some tried and tested levers:

- Make small victories visible (fewer incidents, more regularity)

- Involve a pilot team (HR, maintenance, field)

- Make simple demos with the platform to show what it's for

- Valuing feedback from the field ("thanks to you, we avoided an accident")

- Generate reports they can use easily

What if, in 2025, QSE became a team game?